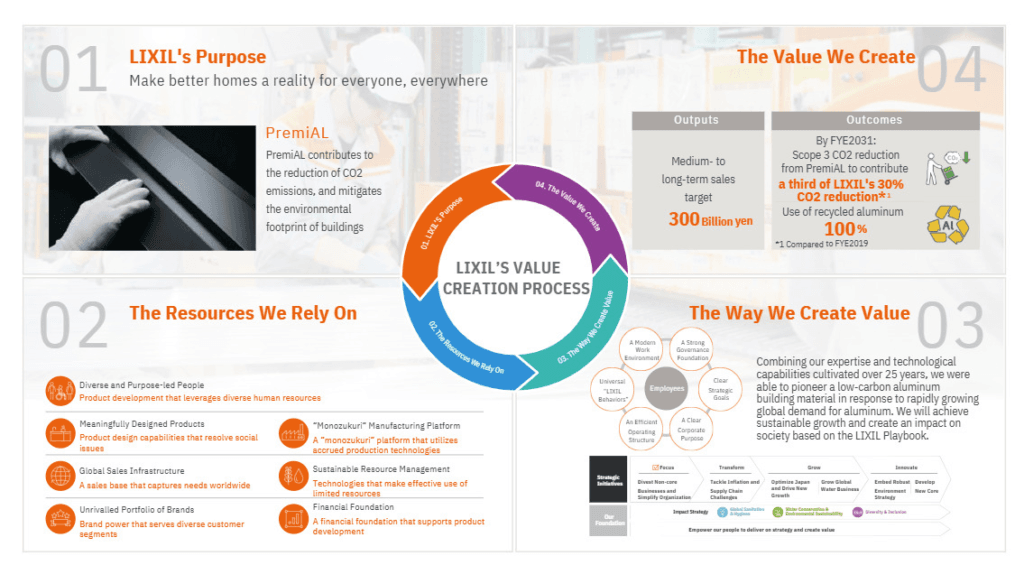

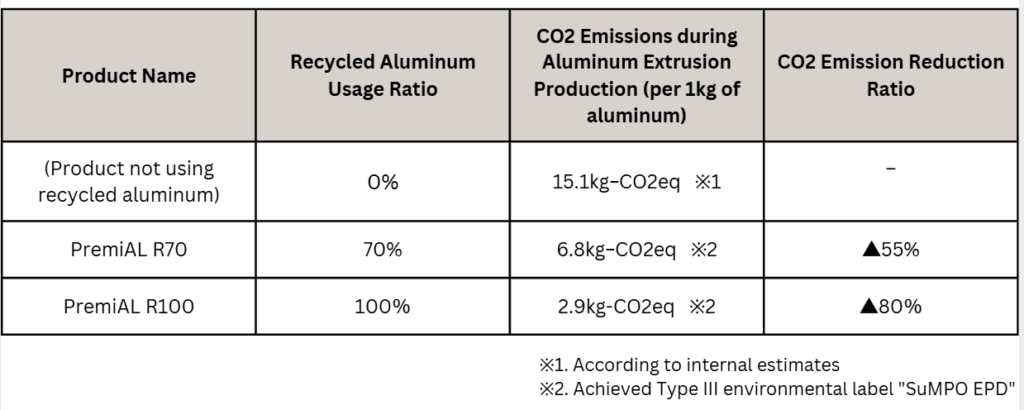

PremiAL is LIXIL’s low-carbon aluminum series. In this series, PremiAL R70 and PremiAL R100 are manufactured using aluminum billets containing at least 70% and 100% recycled content, respectively. Both products are certified by independent organizations and have obtained Environmental Product Declarations (EPDs). This focus on recycled aluminum allows for the quantification of the environmental impacts of using the aluminum material. Additionally, it contributes to enhancing the environmental value of products that use low-carbon aluminum.

The demand for aluminum in the construction and architecture industry is expected to continue to grow. The demand for aluminum – a lightweight and easy-to-process material – is predicted to increase, especially in efforts to reduce energy consumption. To meet this global demand, LIXIL VINA has begun introducing the PremiAL R70 product in the Vietnamese market. They aim to introduce the PremiAL 100 product in the future, emphasizing their commitment to using recycled aluminum.

PremiAL Aluminum Production Process:

1) Collection and Sorting: Scrap aluminum is collected from various sources, including construction sites, industrial manufacturing, and everyday consumer products. The collected scrap is then carefully sorted to remove impurities and ensure the quality of the input material. Given these diverse sources, the use of recycled aluminum becomes integral to the process.

2) Melting and Refining: The sorted aluminum scrap is melted down in specialized furnaces. This process removes any remaining impurities and refines the aluminum to a high level of purity.

3) Casting and Fabrication: The molten, purified aluminum is then cast into various product forms as required, such as sheets, bars, tubes, etc. Further fabrication processes ensure the final products are of high quality and meet the required specifications.

Benefits of Using Recycled Aluminum:

1) Reduced CO2 Emissions: The production process for recycled aluminum consumes significantly less energy compared to producing new aluminum from bauxite ore. This results in a substantial reduction in CO2 emissions, contributing to the mitigation of the greenhouse effect. Therefore, it combats climate change.

2) Conservation of Natural Resources: Recycling aluminum reduces the demand for bauxite ore mining, helping to conserve this valuable natural resource. This, in turn, minimizes the negative impact on ecosystems and habitats.

3) Waste Reduction: Utilizing recycled aluminum decreases the amount of aluminum waste released into the environment. It also alleviates the burden on landfills and waste management systems.

Through PremiAL, LIXIL VINA is committed to continuously striving to develop sustainable products, contributing to building a greener future. By focusing on recycled aluminum, we believe that using PremiAL will help businesses and communities join hands to protect the environment. This creates a sustainable world for future generations.