Our company is committed to producing high-quality products that meet our customers’ requirements. We achieve this through an integrated production management system within our premises. This system encompasses mold making, casting, extrusion, surface treatment, processing, and assembly. It is part of our aluminium manufacturing process. We achieve this through superior production and quality control conducted throughout all processes. This ensures that only products meeting our stringent standards are delivered to our customers.

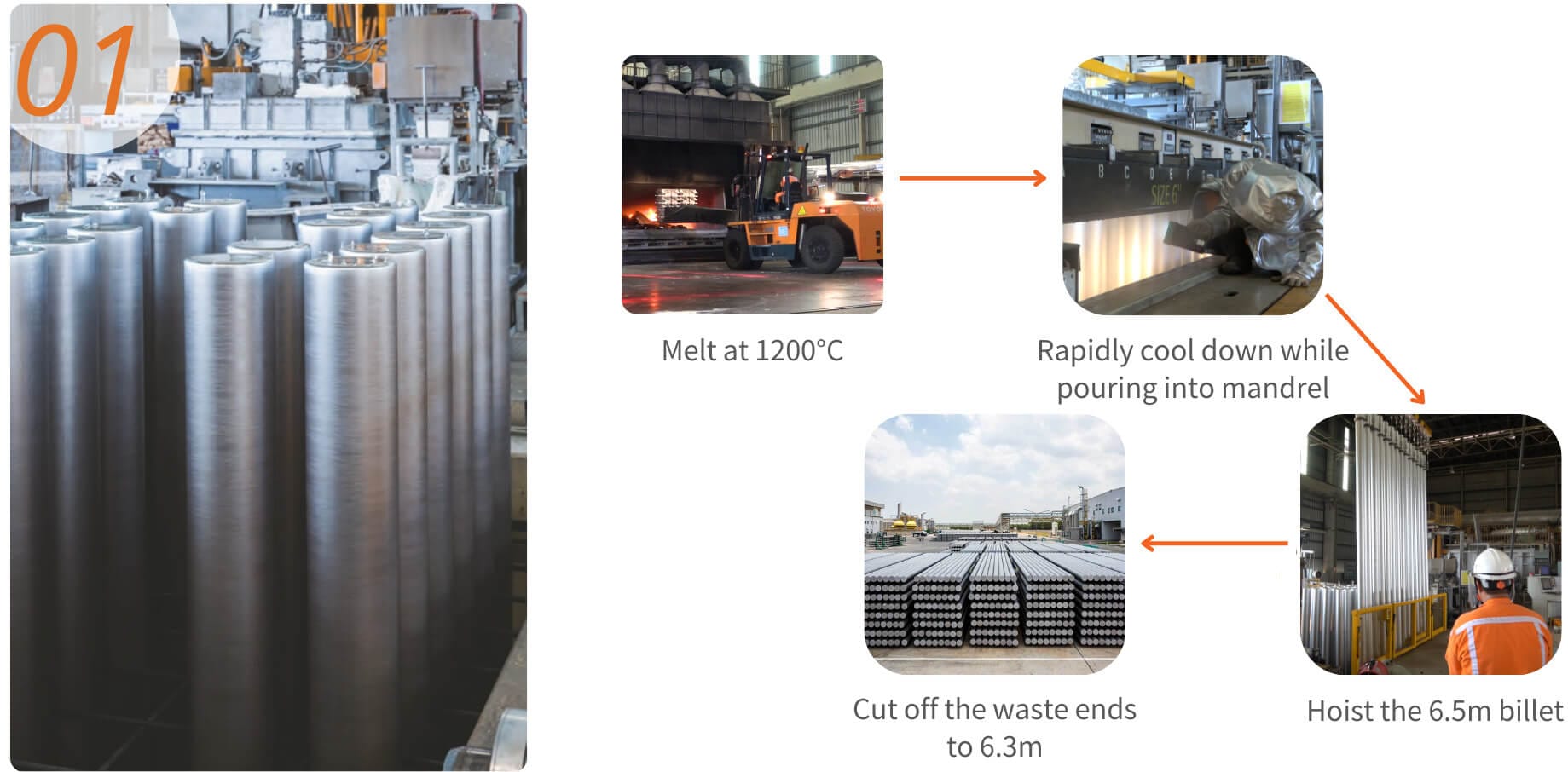

Casting

Melt aluminum ingot in a melting furnace as the first step in the aluminium manufacturing process, and make 6.5m cylindrical billets.

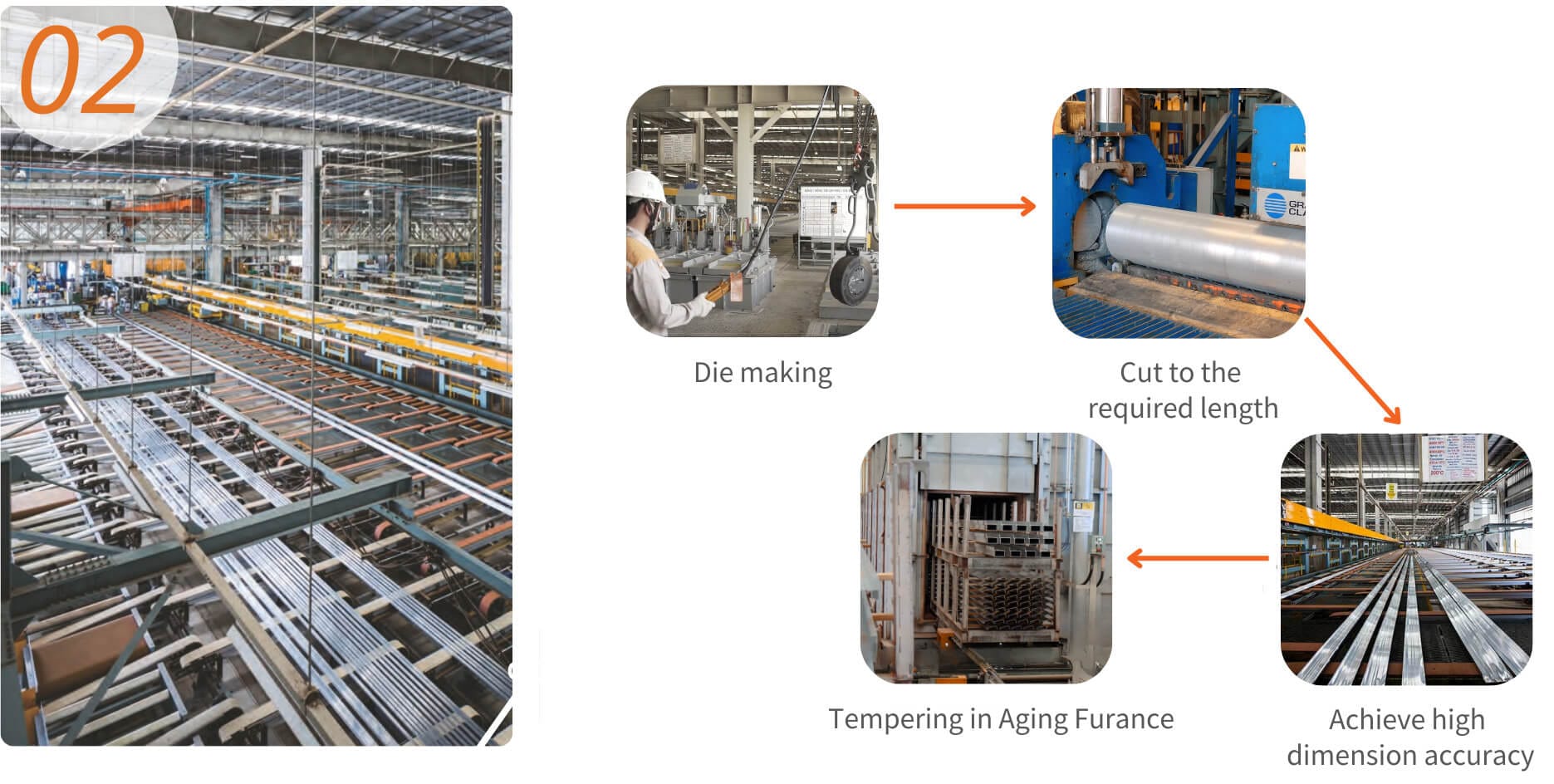

Extrusion

Cut off the billet to required length and extrude it to 50~60m. Each production line equips twin pullers for superior efficiency, facilitating a smooth aluminium manufacturing process.

Die Manufacturing

Extrusion molds are manufactured using computer control through electrode processing and wire electrical discharge machining (EDM). This process is integral to the aluminium manufacturing process.

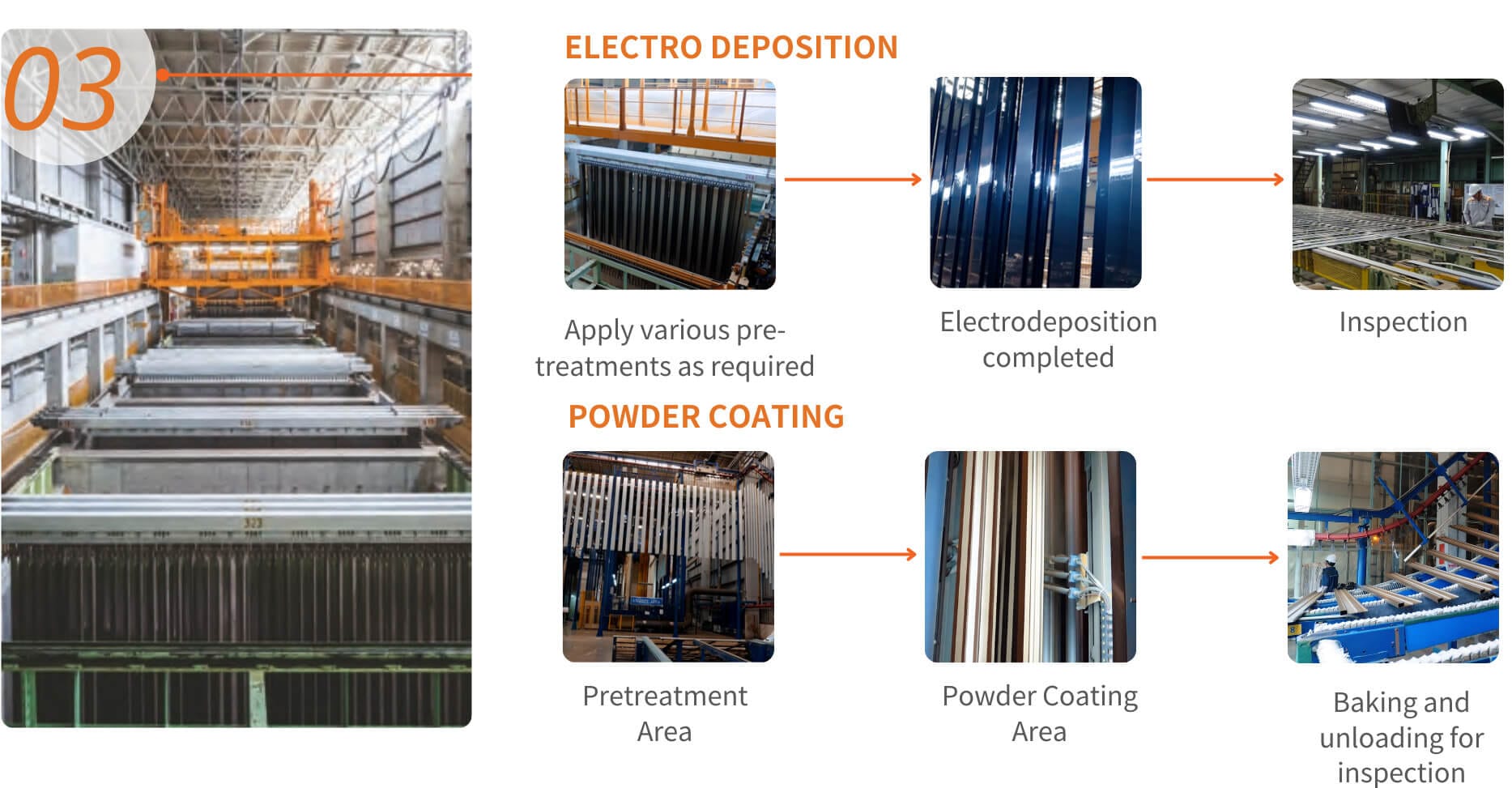

Surface Treatment

LIXIL VINA equips the most advanced lines of Electro deposition coating and Powder Coating in its ongoing aluminium manufacturing process.

WOOD GRAIN POWDER COATING

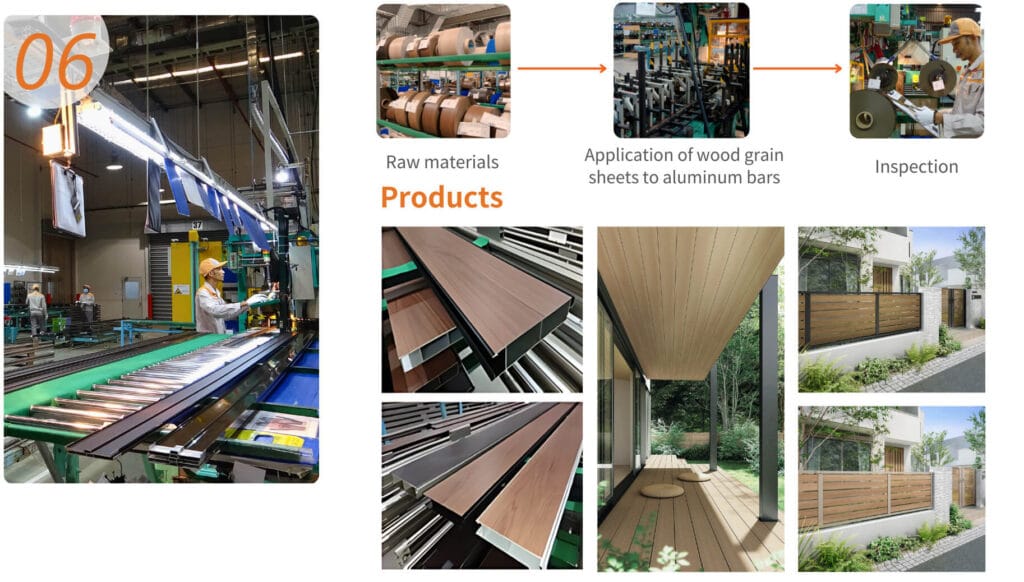

Our wood grain coating process combines art and technology. It creates products with a high aesthetic sense. These products meet the needs of customers seeking delicacy and luxury.

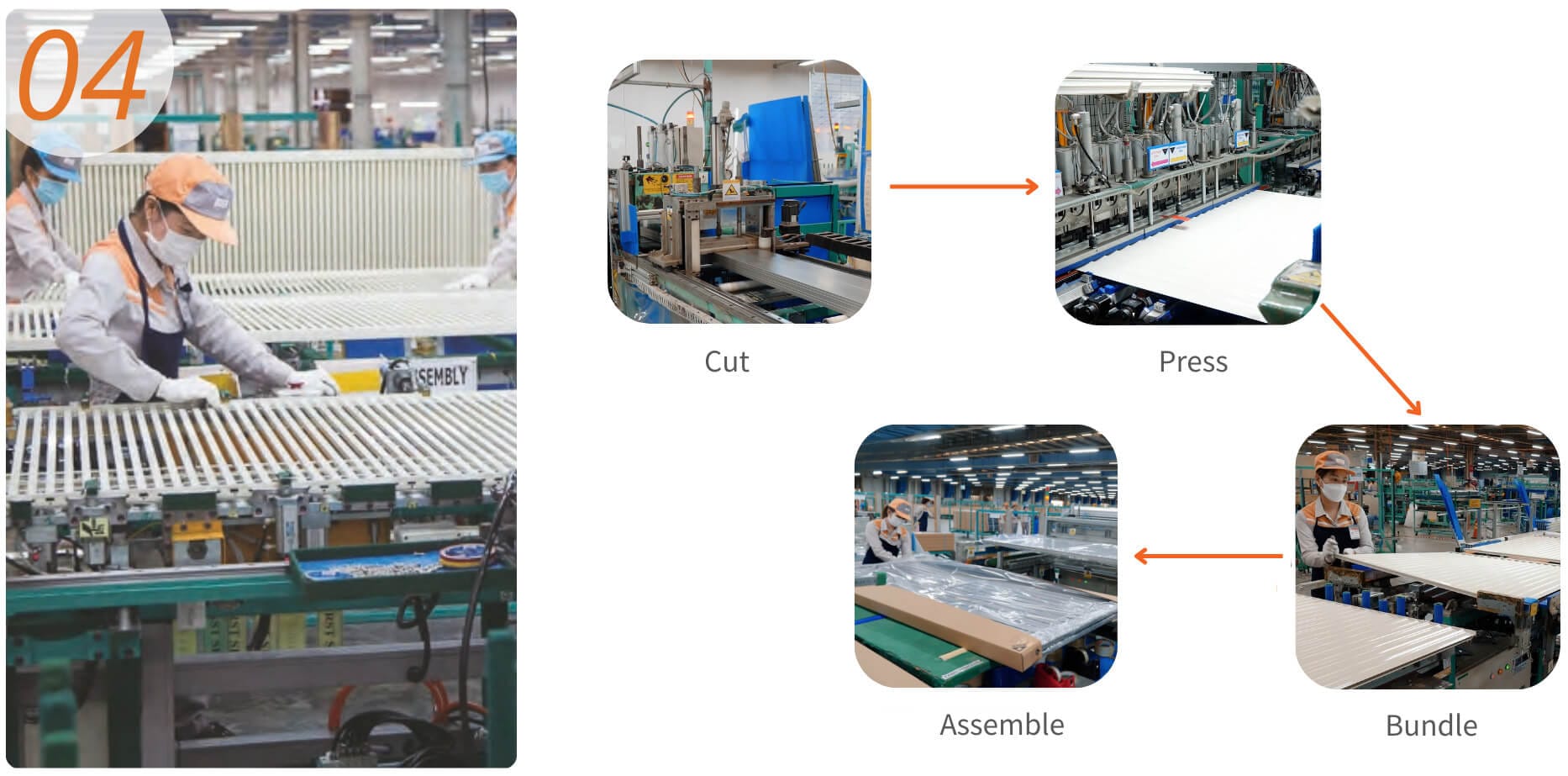

Fabrication

Profiles are cut and fabricated, assembled, and packed for shipping after surface treatment. This completes another step in the aluminium manufacturing process.

CUSTOM MANUFACTURING SERVICES

This is a one-stop service at LIXIL’s manufacturing plants. It utilizes machinery for punching, cutting, drilling, and assembly based on Japanese technology. Moreover, the products can be flexibly customized to meet the demands of customers.

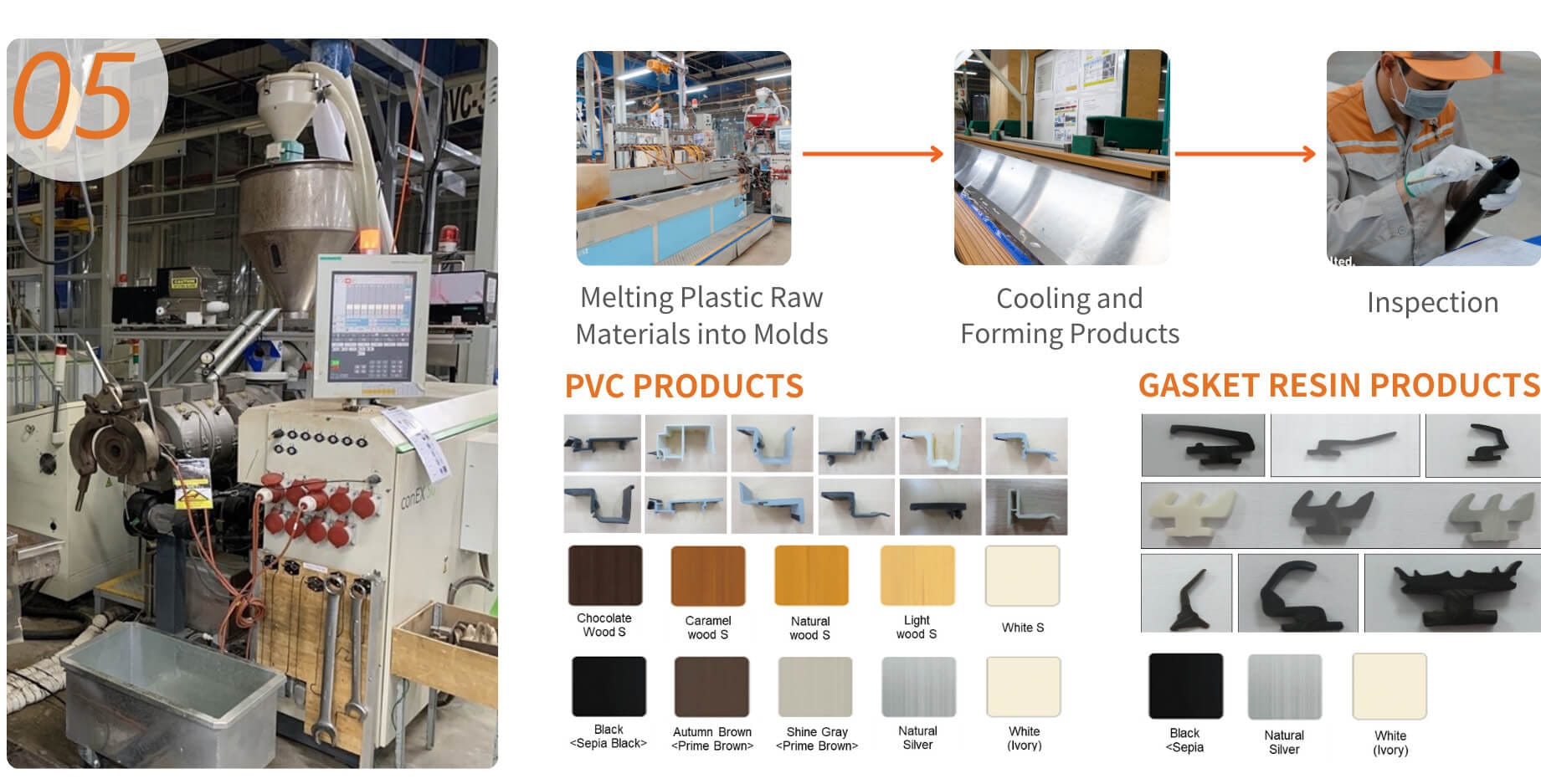

Plastic

Our factory also features a plastic production process. Here we manufacture rigid and soft resin molded parts and bar materials through the resin extrusion process. This integrates similar methods as those in the aluminium manufacturing process.

Custom manufacturing service

The Plastic division at LIXIL VINA is equipped with advanced manufacturing technology. It also has a team of specialized engineers to meet customers’ unique demands. They produce high-quality plastic products that precisely match technical standards and designs.

WRAPPING

Besides coating technology, LIXIL VINA uses a wrapping method to apply wood grain sheets to the surface of aluminum bars. This enhances the aesthetic appeal of the products. It thereby adds another dimension to our aluminium manufacturing process.