At LIXIL VINA, we are dedicated to manufacturing superior products that precisely meet our customers’ diverse requirements. Our aluminum production process is achieved through a comprehensive, in-house integrated production management system, encompassing every stage from mold making, casting, and extrusion to surface treatment, precision fabrication, and final assembly. Our commitment to excellence is underpinned by rigorous production protocols and meticulous quality control implemented across all processes. This ensures that only products adhering to our stringent standards reach our valued customers.

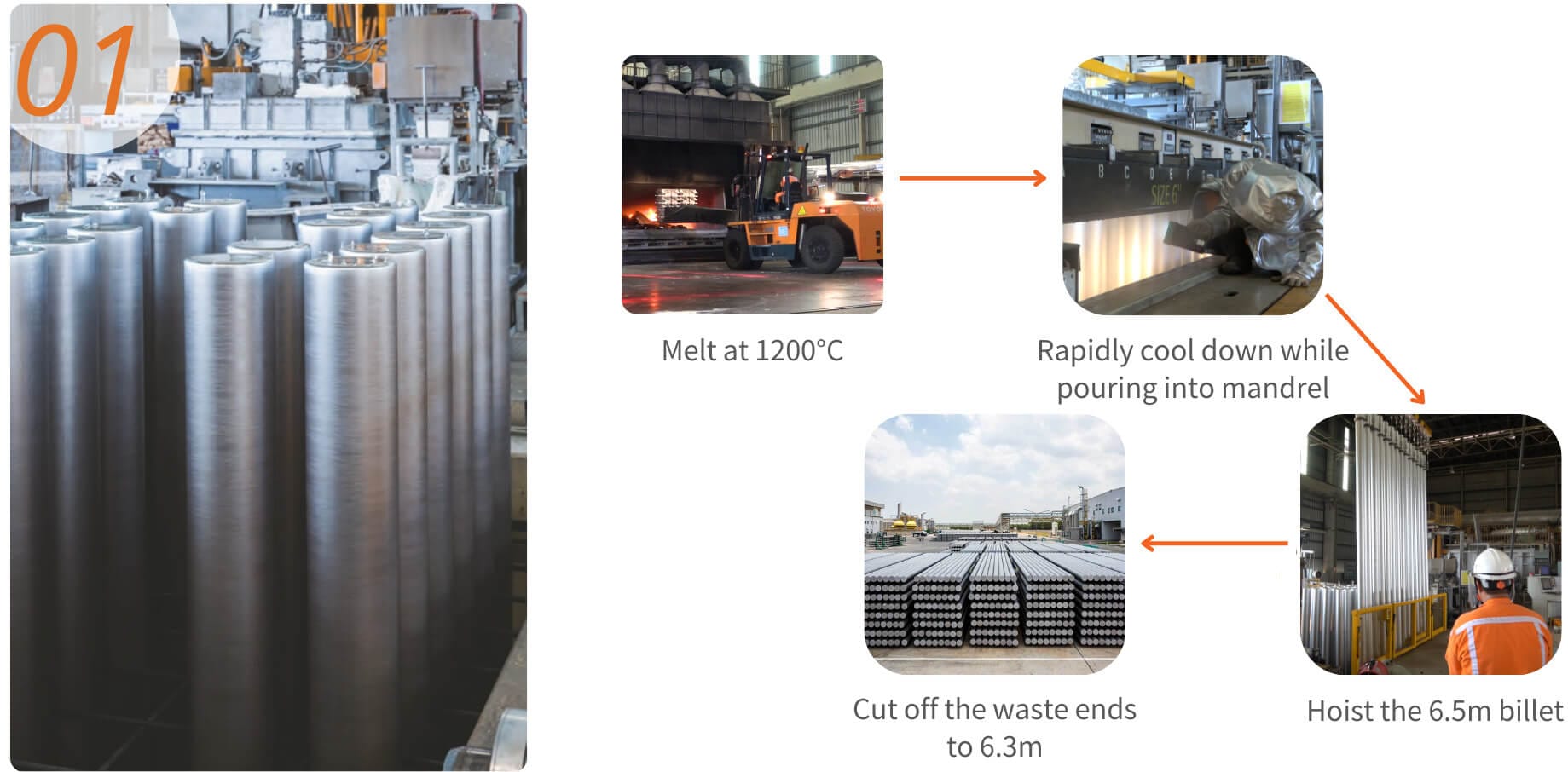

Casting

The Foundation of Quality The process begins with melting high-grade aluminum ingots in specialized melting furnaces. These are then cast into 6.5-meter cylindrical billets, forming the initial stage of the aluminum production process. This crucial first step ensures the purity and structural integrity necessary for high-performance aluminum.

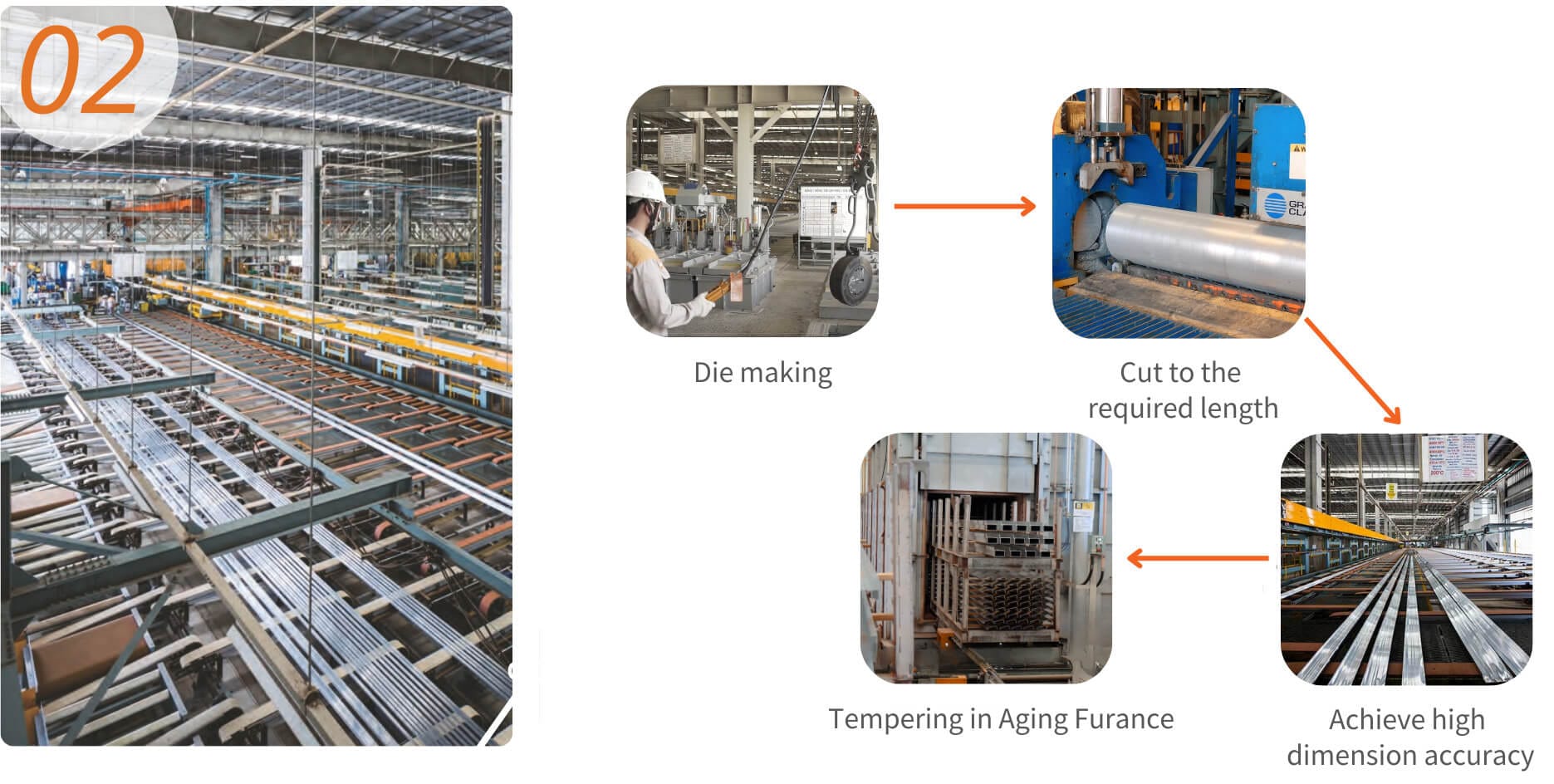

Extrusion

Shaping Innovation Billets are precision-cut to the required lengths before being heated and forced through a die in the extrusion process, yielding aluminum profiles of 50-60 meters. Each of our advanced production lines is equipped with twin pullers, significantly enhancing operational efficiency and output consistency for complex designs, all integral steps in the aluminum production journey.

Die Manufacturing

Our extrusion dies are meticulously crafted using state-of-the-art, computer-controlled processes, including electrode processing and wire electrical discharge machining (EDM). This ensures exacting tolerances and superior surface finishes for all extruded profiles, integral steps within the entire aluminum production workflow.

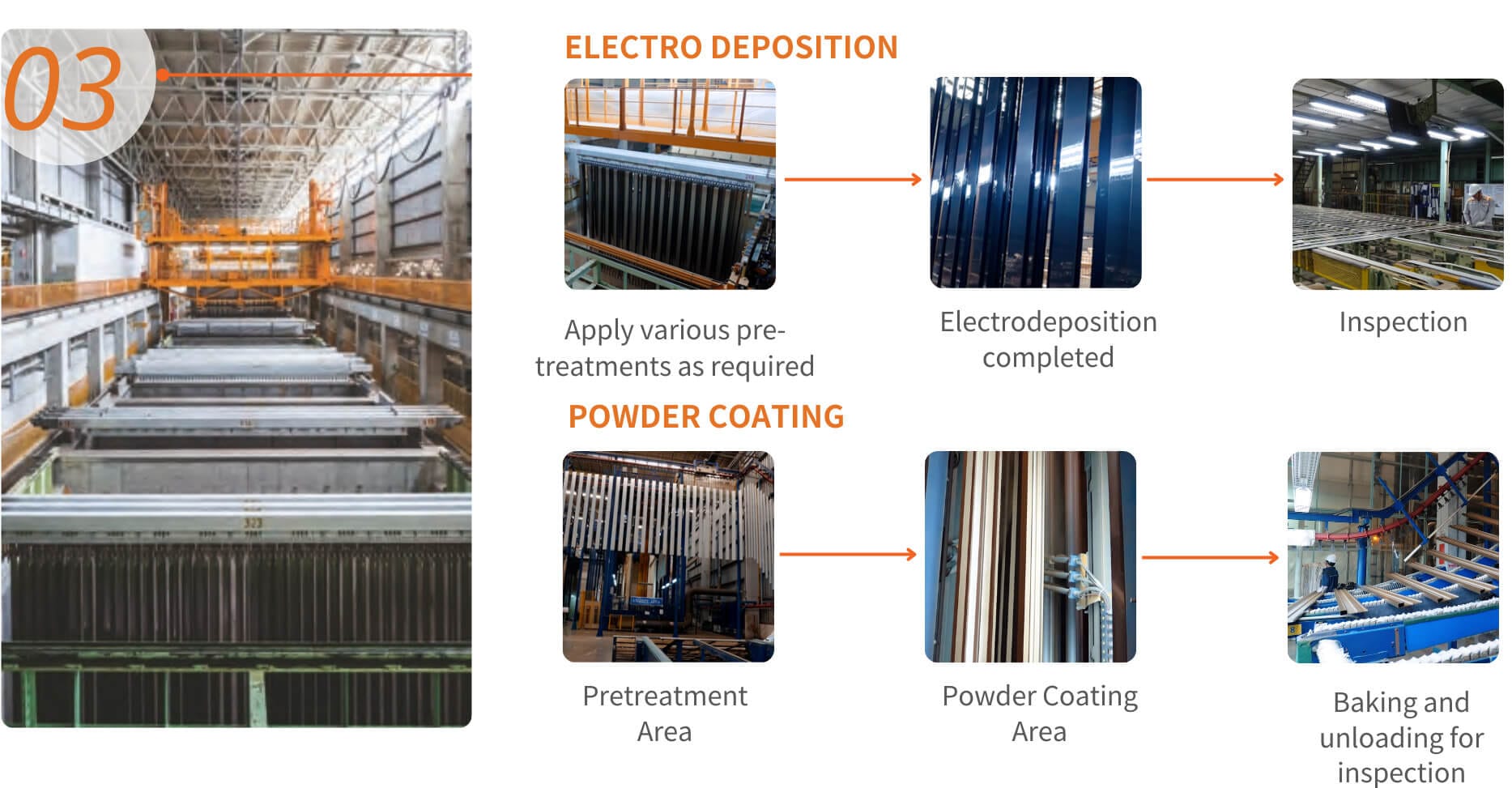

Surface Treatment

Durability and Aesthetics LIXIL VINA utilizes cutting-edge surface treatment lines, featuring advanced Electrodeposition (ED) Coating and Powder Coating technologies. These processes, as integral parts of aluminum production, provide exceptional durability, corrosion resistance, and a premium finish to our products, available in a wide array of colors and textures.

WOOD GRAIN POWDER COATING

The Beauty of Nature, Engineered to Last Our specialized Wood Grain Powder Coating process artfully blends technology with aesthetics. This innovative technique creates products with a sophisticated, natural wood appearance, catering to customers who desire elegance and a luxurious feel without compromising on the durability of aluminum—part of the aluminum production strategy.

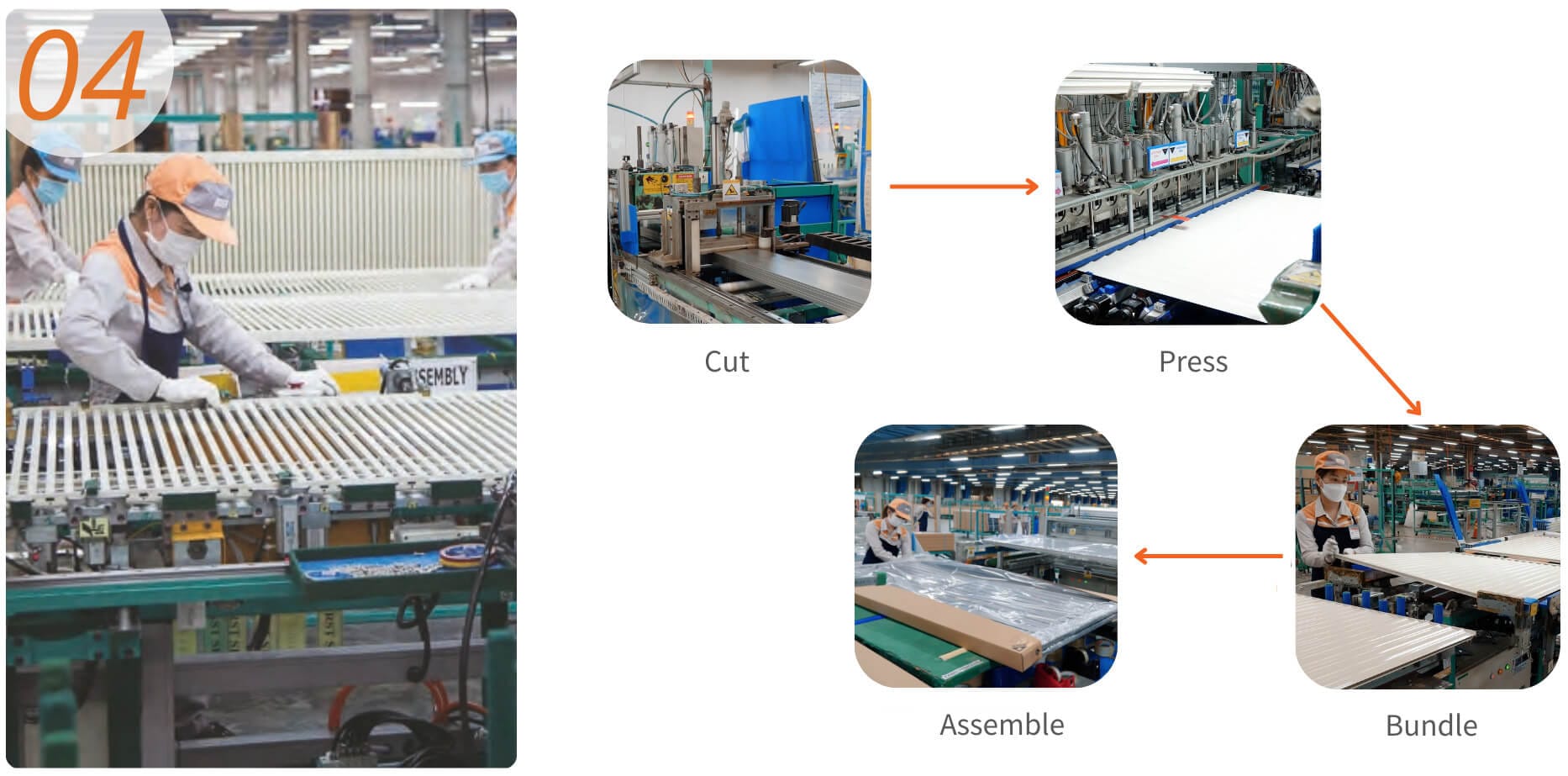

Fabrication

Assembling Excellence Following surface treatment, aluminum profiles undergo precise cutting, fabrication, and assembly according to customer specifications. Our skilled technicians ensure every component is perfectly aligned and integrated. Finished products, resulting from our aluminum production system, are then carefully packed for secure shipping worldwide.

CUSTOM MANUFACTURING SERVICES

This is a one-stop service at LIXIL’s manufacturing plants, utilizing machinery for punching, cutting, drilling, and assembly based on Japanese technology. These custom services support the aluminum production process, allowing products to be flexibly tailored to meet the demands of customers.

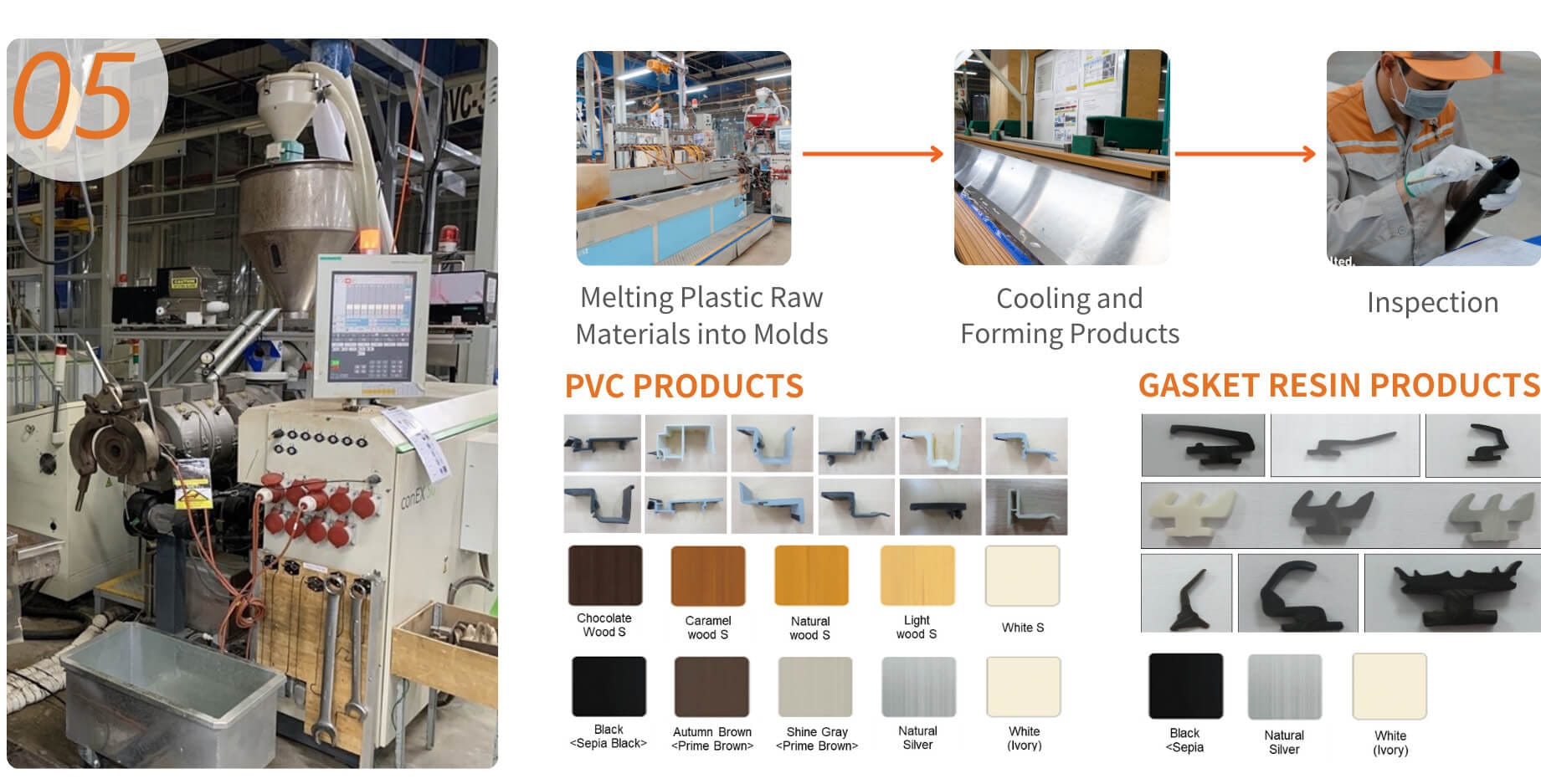

Plastic

Versatile Solutions Beyond aluminum, LIXIL VINA’s facility incorporates a dedicated plastic production process. We specialize in manufacturing a wide range of rigid and soft resin molded parts, as well as bar materials, through advanced resin extrusion techniques. This capability supports our broader aluminum and plastic production processes, allowing us to offer a spectrum of integrated solutions.

Custom manufacturing service

The Plastic division at LIXIL VINA is equipped with advanced manufacturing technology and a team of specialized engineers to meet customers’ unique demands, producing high-quality plastic products that precisely match technical standards and designs.

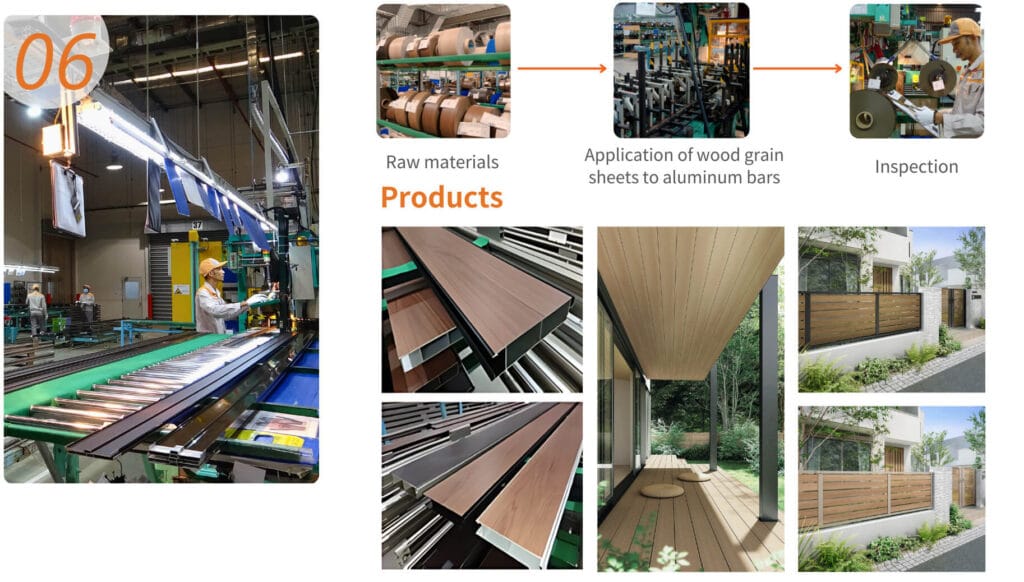

WRAPPING

Beside of coating technology, LIXIL VINA uses a wrapping method to apply wood grain sheets to the surface of aluminum bars, enhancing the aesthetic appeal of the products. This method showcases the versatility in the aluminum production process.